So, an Inspector might have recently paid a visit to your workplace and left you with some kind of ‘report’. Now, it’s likely that this report will be an Entry Report, Improvement Notice or a Prohibition Notice. But many businesses are often unsure about what these actually mean and what they need to do next. So, here’s some brief advice to start you off.

First of all, the Entry Report simply is a record of the visit. It advises that an inspector has been onsite, and advises the purpose of their visit.

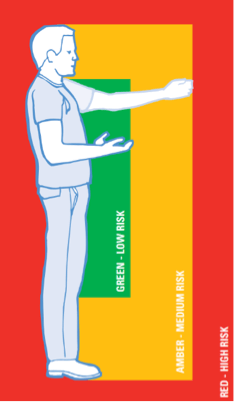

Improvement Notices and Prohibition Notices are different. These notices are issued when an Inspector identifies that there’s been a level of non-compliance with the health and safety laws. Note that these notices are not issued on a whim, or because the inspector simply thinks that your workplace could improve in some areas. They are serious. And, as such, they should be taken seriously because it is an offence not to comply with these.

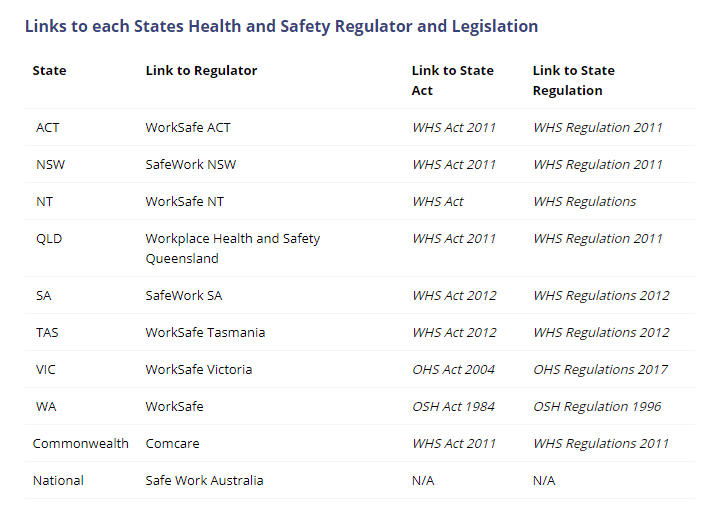

Though the notices may vary slightly state to state, here’s a run down of these two types of notices and what they mean;

Improvement notices

These notices are issued when an Inspector believes that there is a safety issue that needs to be fixed within your workplace. These notices usually don’t prevent you from continuing business, as the issue is generally required to be resolved within a prescribed timeframe provided by the inspector. The inspector will generally revisit your site to ensure the required improvements have been made.

Prohibition notices

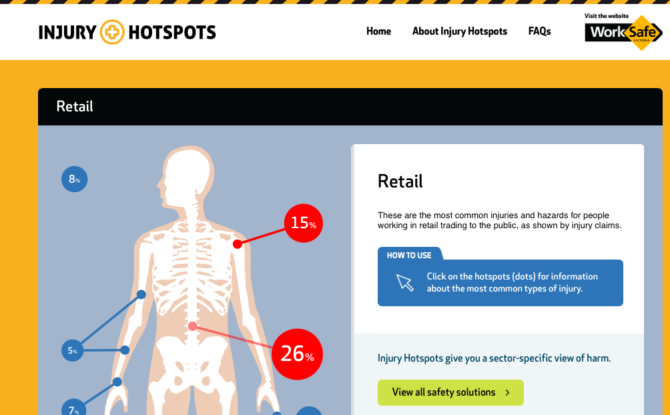

These ones are very serious. An Inspector will issue these if they believe there is a risk to your workers from‘an immediate or imminent exposure to a hazard’ within the workplace. When these notices are issued you will need to stop all activity related to that hazard immediately until it is correctly managed. In some instances you may need to change the way you work moving forward as part of that management.

If you do receive one of these notices, do make sure that you fully understand what the notice has been issued for. If not, seek to clarify this with the Inspector, with legal counsel or with your regulator. If you don’t believe there is a breach, there is often an opportunity to place the notice under an internal review. However, be aware, there are often timeframes for such lodgment – so act fast. Once you understand the notice, make sure you plan to ensure that you have enough time to sufficiently correct the matter.

Now it goes without saying that there are always ways you can improve health and safety management in your workplace. So, if you are looking for solutions so that you can avoid receiving notices like the ones mentioned above again, check out how Safety Champion software can make things that much easier!