Why Safety in Manufacturing Matters

Manufacturing is the backbone of Australia’s economy, but it also remains one of the industries with the highest safety risks. From operating complex machinery to managing chemical exposure, Plant Managers and businesses in the sector carry significant responsibility, not only to maintain compliance but to protect their workforce and safeguard operations. Today, building a strong culture of safety is more than a legal obligation; it’s a competitive advantage.

Exploring Top 3 Common Safety Challenges in Manufacturing

1) Workforce Diversity

Manufacturing teams often bring together a wide range of experience levels, cultural backgrounds, and languages. While diversity is a strength, it can also create gaps in understanding safety procedures and expectations. Consistent communication and accessible training are vital to ensure everyone understands their role in creating a safe workplace.

2) Dangerous Machinery and Plant Equipment

Heavy machinery is at the core of production, but it brings with it risks of crush injuries, entanglement, or mechanical failures. Ensuring that equipment is maintained, inspected, and only operated by trained staff is critical. Poorly managed plant safety can lead not only to injuries but also costly downtime and damaged reputation.

3) Exposure to Noise, Dust, and Chemicals

From loud production floors to airborne dust and hazardous substances, workers in manufacturing environments are often exposed to health risks that can have long-term impacts. Managing these hazards requires monitoring, control measures, and accurate record-keeping to demonstrate compliance with regulatory requirements.

Best Practices for a Safer Manufacturing Environment

- Regular Risk Assessments: Systematic reviews of machinery, workflows, and work environments help identify hazards before they become incidents.

- Accessible Safety Training: Tailored programs that accommodate diverse language and literacy levels improve understanding and engagement.

- Equipment Inspections and Maintenance: Proactive scheduling of inspections prevents unexpected breakdowns and keeps staff safe.

- Health Monitoring and Reporting: Keeping track of worker health checks, noise exposure, and chemical handling is essential to long-term safety and compliance.

- Clear Documentation and Accountability: Having an auditable trail of actions, incidents, and training ensures regulatory compliance and builds trust with stakeholders.

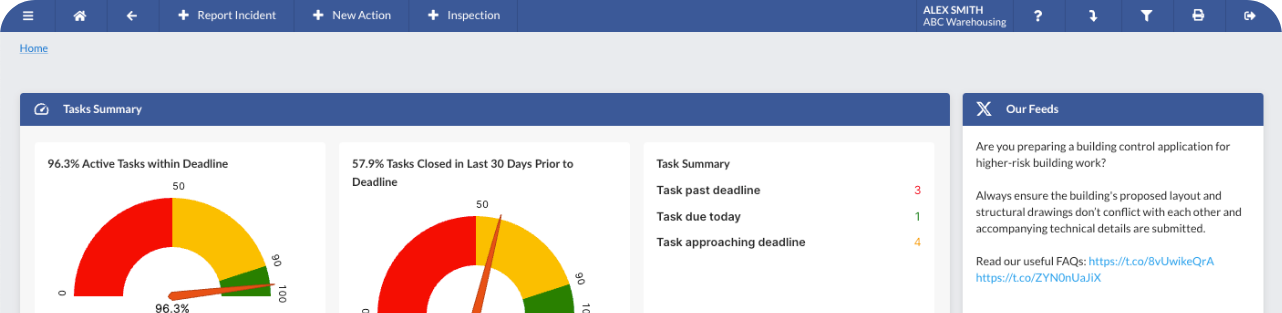

How Safety Champion Supports Manufacturing

Safety Champion software is designed to simplify and strengthen safety management in the manufacturing industry. By centralising safety processes, the platform helps decision makers:

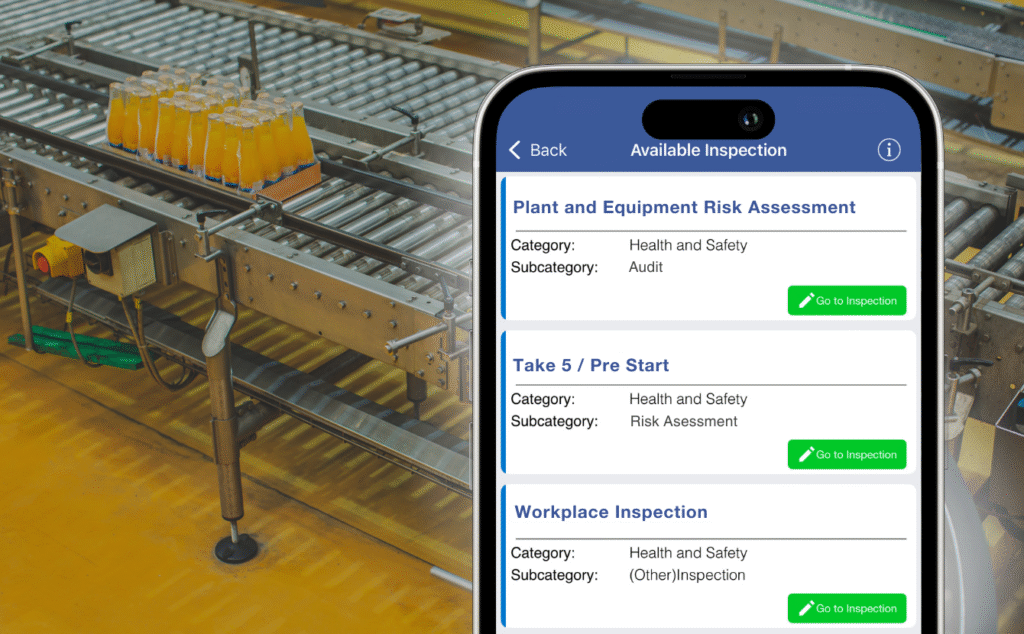

- Complete plant and equipment inspections: Ensure nothing is missed and meet compliance deadlines effortlessly. Schedule custom reminders and ensure your operations run smoothly and safely.

- Assign the right person to the right task: Review licences and certificates to ensure qualified workers undertake tasks that require specific knowledge and skills.

- Document Instantly: Capture incidents in real-time with photos and details, so they don’t get lost in paperwork.

- Track exposure and health monitoring records in one place, making it easier to demonstrate compliance with WHS regulations.

- Generate real-time insights and reports, giving managers visibility over hazards, incidents, and corrective actions.

- Boost Employee Engagement: Create a culture of safety by empowering workers with easy mobile access to report hazards, complete checklists, and stay informed.

- Streamline safety communication across diverse teams with easy-to-use digital tools.

With Safety Champion, manufacturers can move from manual processes with a system that ensures accountability, improves efficiency, and, most importantly, keeps people safe.

A Safer Future for Manufacturing

Manufacturing will always involve unique risks, but with the right strategies and tools in place, those risks can be effectively managed. By committing to safety best practices and leveraging modern solutions like Safety Champion, decision makers can create safer, more resilient, and more productive workplaces.